EME234 HF Magnetic Loop Antenna Module

- EME234 Active Module Description:

Updated June 2022! - EME234 Application Block for EME215:

- EME234 Application Block for EME195H:

New June 2023! - Kit Constructors Alert:

Updated Jan 2022! - EME234 Kit Construction Notes:

- EME234 Kit Performance Tests:

- Antenna & Enclosure Mounting:

- Kit changes and Updates:

Updated Jan 2022! - Buy a EME234 Kit:

The HF Active Magnetic Loop Antenna module has been designed to be easy to construct and install, and covers a wide frequency range from 1 to 50MHz. It is particularly useful for those that have antenna restrictions or limited space to install a full size receive only antenna, or have very high man made noise levels. The magnetic loop is particularly effective at reducing power line and common mode type noise and being a figure 8 pattern with vertically polarized signals, can be rotated to further notch interference. The amplifier is based on the design by Chavdar Levkov LZ1AQ, and incorporates static and lightning protection, and has a broadband 50ohm output impedance suitable for driving most receivers. The amplifier is designed to be used with a 1 metre single turn loop, and a balanced low input impedance common base amplifier is used to match the input. Low cost RF Transistors are used as the active devices, which produce high output second and third order figures reducing the possibility of inter modulation on received signals. The design incorporates power supply decoupling so that power can be fed to the Active circuit via the coaxial cable.

Test on prototypes indicated that high levels of broadband noise across the Radio spectrum could be nulled completely allowing many weak signals to be heard with very high signal to noise ratios. The same signals on a dipole were either unreadable or the noise made it difficult to copy them. It would be useful to be able to remotely rotate the loop so that it could be more useful at reducing interference. The null is very sharp maybe on a few degrees.

In very strong AM broadcast areas, some lower quality receivers without good filtering may suffer from inter modulation from strong signal overload. A suitable 1.8MHz high pass filter should be fitted at the receiver input to reduce broadcast band signal levels.

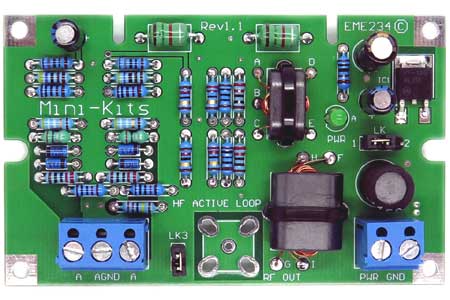

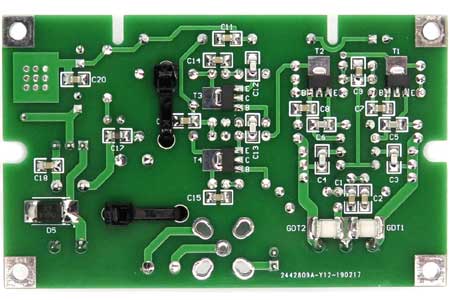

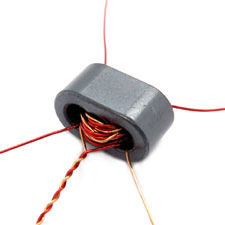

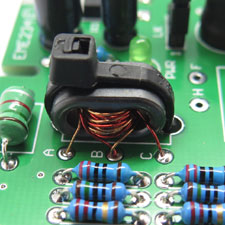

The images below show both sides of the board. The construction is quite easy if you start with the SMD components on the bottom side of the board first, and then fit the conventional leaded components after. The only difficult part is the winding of transformer TFMR1 as the windings have to be correctly connected for the correct phasing polarity. An incorrectly phased transformer cancels the signals and produces no gain. Click the pictures below for a more detailed view.

The recommended Antenna is constructed using off the shelf hardware from Bunnings Hardware stores in Australia. A 3 metre length of 25mm diameter PE100 high pressure pipe is bent into a loop and is used to house a loop wire element, Bunnings Part# 4811263. A 25mm Philmac Poly T piece, Bunnings Part# 4813797 is used for the connection to the ends of the poly pipe, and the T piece is mounted onto a 3 metre long 25mm diameter galvanized steel pole, Bunnings Part# 1130457. Thanks to Tom VK5ZTS and Richard VK5ZLR for the Poly tube loop idea.

1/ A 4 metre long length of stranded 3mm diameter PVC covered wire is run inside the poly pipe for the loop antenna element. You can use a larger diameter if you like but it probably will make no difference with received signal or performance. Bend the 25mm Poly tube into a loop and connect it to the Poly T piece and firmly tighten the gland nuts. On the underside of the loop drill 2x 3.5mm holes 10mm out from the T piece nuts at an angle to suit feeding the 3mm PVC covered wire through the tube. Remove the T piece from the poly pipe and feed the 3mm wire through one hole in the poly tube until it exits the other end of the tube. Feed some thin tinned copper wire through the second 3.5mm hole and out through the poly tube end, and solder it to the end of the 3mm PVC wire. Pull the tinned copper wire and feed the end of the 3mm wire through the second 3.5mm hole to a length of around 40cm out of the hole in the poly tube. At least 35cm of 3mm wire from each end of the poly tube is needed to reach the Active module.

2/ Cut the steel pole to a 2.5 metre length and drive the pole vertically 0.5 metres into the ground. The recommended height of the bottom of the loop is 2 metres above the ground which is at a height that will clear most obstructions, but is still close to the ground avoiding pickup of noise on the outer of the coaxial cable.

3/ Mount the Poly T piece with loop onto the top of the steel pole, and then mount the GME enclosure directly beneath the Poly T piece using the supplied cable tie.

4/ Work out the length required for the ends of the 3mm wires so that it can be routed evenly in length to the Active modules A connections. Use small cable ties to tie the two wires together as shown in the picture below, routing them evenly and away from the galvanized pole to the Active modules A terminals. Drill a hole in the galvanized pole just under the masthead enclosure and connect a crimped eyelet terminal ground wire from the pole to the Active modules AGND connection. This adds some lightning and static protection to the Active circuit.

5/ Run a length of RG6 Quad coaxial cable from where the Active module is located to the receiver. The cable should if possible be run across the ground to avoid noise pickup. Fit suitable male F connectors onto the coaxial cable, and cable tie it to the pole.

1/ Poor reception or very low signals can sometimes be due to the windings on the primary of TFMR1 being reversed. This would cause the signals from T3 and T4 to cancel in the transformer.

2/ There has been a report of a BNC PCB socket that had an intermittent short internally. The issue was traced to a small piece of plating that was loose inside the connectors cavity. Thanks to Michael VK5ZEA

3/ Poor low frequency response can normally be traced to incorrect capacitors fitted for either C14 or 15.

4/ Modification for a lower frequency response to cover the 472kHz band can be done at the expense of an increase of signals levels on the AM broadcast band. Change C5 and C6 to 0.1uF.