EME237 70cm Preamplifier

- EME237-70CM Description:

Updated! July 22

- EME237-70CM Application Block

- Kit Constructors Alert:

Updated! July22 - EME237-70CM Kit Notes:

Updated! June21 - EME237-70CM Kit Performance Tests:

- Connection to a Transceiver:

Updated! Nov 23

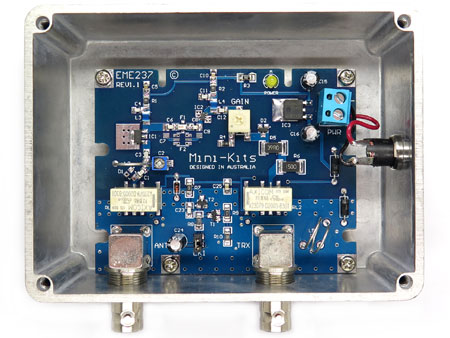

- Mounting into a Die cast Enclosure:

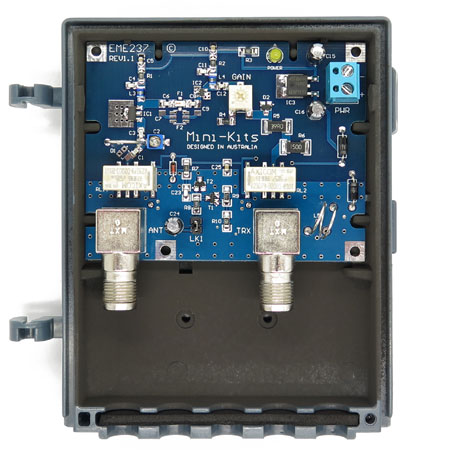

Updated! Feb25 - Mounting into a Masthead Enclosure:

- Product Changes and Updates:

Updated! Jan23 - Buy A EME237-70CM Kit:

- Buy A EME237-70CM-MH Built Product:

- Buy A EME237-70CM-1590S Built Product:

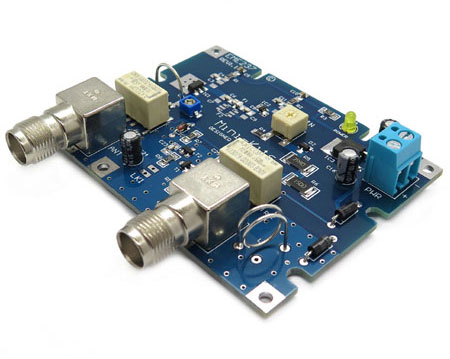

The EME237-70CM is a High performance masthead mount Receiver Pre-amplifier that is specifically designed for the 70cm 430 to 450MHz band. The Pre-amplifier has an adjustable 20 to 29dB gain, and can be used to optimize gain distribution for coaxial cable losses and the total gain of the receiver system. The design uses the Mini-Circuits PGA-103 that has a very high dynamic range and ultra low 0.38dB noise figure. The input circuit consists of a tuneable T type filter that can be tuned to optimize the noise figure to less than 1dB while giving high rejection of signals below 200MHz. The output of the PGA-103 is filtered with a low pass filter giving high rejection of signals above 500MHz, and is then further amplified by a low noise Avago MGA82563 PHEMT MMIC. The design incorporates high isolation RF changeover Relays to bypass the pre-amplifier when not required, or when RF power from a transmitter is applied to the antenna. An on board bias tee ( DC power injector ), allows the pre-amplifier to be antenna mounted and powered via the coaxial cable. The pre-amplifier is able to handle 50 Watts ( +47dBm ) CW, when unsequenced, or up to 100 Watts ( +50dBm ) PEP when sequenced.

The PC board is designed to suit a GME mast head enclosure which makes installation easy and provides high protection of the circuitry from weather.

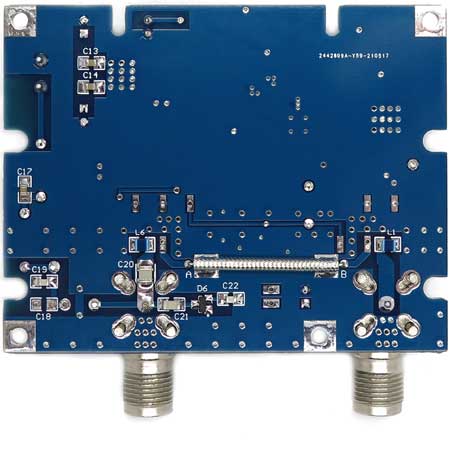

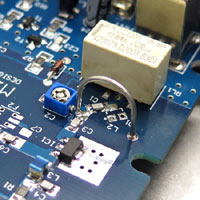

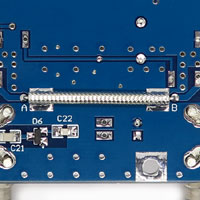

The pictures below are a final revision so should be carefully followed in construction. Be careful when fabricating and fitting L5 as it needs to be done correctly to achieve the lowest transmit power loss and high return loss. On a prototype I was not very careful when fitting the QF0.085 cable under the board between points A and B, so this created a short from the braid to one on the PCB pads which was not very obvious so check this carefully. Slight filing of the two slots at the top of the board is required to fit the GME masthead enclosure. This was unfortunate as the PCB manufacturer made a slight mistake with the board route out. The board should be fully cleaned with Isopropyl Alcohol and thoroughly dried using a hair drier before testing. Through loss tests may not be achievable if there is Isopropyl still under the connectors and relays. The performance tests below are as measured on a number of built products and were nearly all identical. BUY THIS PRODUCT

A Hammond 1590S or 1590SFL die cast enclosure is ideal for mounting the pre-amplifier module for in shack use. The enclosure could also be mounted inside a weather proof enclosure at the Antenna. Only TNC or BNC type R/Angle PCB mount connectors can be used for minimum loss when mounting into this type of enclosure.

1/ First before the PCB is populated with components, it needs to be used as a template to mark 4 x M3 drilled holes for mounting the PCB. The PCB is normally pressed hard up against the internal wall of the enclosure to mark the holes with a felt tip pen.

2/ The two holes required for the RF connectors can vary with the type and brand of connectors due to the height and outer diameter of the connector. When using the BNS11D connectors, the PCB spacers have been changed from M3x12mm to M3x10mm high brass spacers. M3 shakeproof washers are then used to increase the spacer height to around 11mm to suit the 12mm enclosure holes ( 17mm ) from the top of the enclosure wall. Refer to the pictures below for the recommended hole positions.

3/ The spacers are mounted to the enclosure using M3x6mm countersunk screws.

This is for advanced constructors that have experience and access to a workshop with metal working tools. The basic tool requirements are a drill press, Vice, M1.5, M3, M6, M12, and 1.4 inch drill bits, scriber, metal punch, and a hammer.

-

Place an un-populated EME237 PC board into the enclosure hard against the enclosures internal wall, and mark the four mounting holes using a fine felt tip pen. Using a centre punch, mark the centre of the mounting holes for drilling. Drill out the four holes starting with a 1.5mm drill bit followed by a 3mm bit. Counter sink the holes on the bottom of the enclosure to suit M3 x 6mm countersunk screws.

-

Carefully mark and drill two 13mm holes in the die cast enclosure as shown in the picture above to suit the BNC connectors, and a 8mm hole to suit the 2.1mm DC connector. Some filing of the holes for the BNC connectors may be required if you have not drilled accurately.

-

Mount the 4x M3x12mm brass spacers onto the PC board module using the M3x6 panhead screws.

-

Mount the completed PC board module into the enclosure and fasten the module to the enclosure with the M3x6 countersunk screws from the botton of the enclosure. Use some thread lock on the BNC connector nuts doing them up just enough so that they are firm.

-

Solder the red and black hookup wire to the 2.1mm female DC connector and cut to around 4cm length. Strip around 8mm from the wire ends and tin solder for connection to the board.

-

Connect the red and black wire ends to the PWR terminal block on the module.

-

Mount the 2.1mm DC connector to the enclosure rotating it to the position as shown in the pictures. Carefully fully tighten the nut using a small spanner or wrench.

-

Finally tune the pre-amplifier as per the Kit construction notes for the best noise figure.

The GME Masthead enclosure will accept cables up to around 8mm in diameter. Therefore larger cables like RG8/213 cannot be used. Larger cables would also place too much strain on the TNC sockets on the pre-amplifier board. To connect the Antenna feed line to the pre-amplifier, and pre-amplifier output to the main feed line, we recommend the use of CNT®240 ( 240 Type ) cable with crimped TNC connectors. CNT®240 is double shielded and has losses similar to RG213 cable, but has a much smaller 6mm diameter. Use the website search box and search for 240 series cable and connectors.

1/ Mini-Kits cannot be expected to take responsibility to make this product work on your Transceiver, we can only give guidance on how best to use this product. Using this product with high power FM or SSB modes does have the risk of damaging the Pre-amplifier if the transceiver switches from RX to TX modes faster than the pre-amplifiers relays. Some protection is built into the pre-amplifier circuit including a RF sensing circuit and Limiter diode protection, but high RF levels into the pre-amplifier before it has fully switched from RX to TX mode can damage the pre amp. Some Transceivers are prone to producing a spike on the RF output when going into transmit mode. This can be due to the ALC in the Radio not acting fast enough. This is where a sequencer circuit is useful to sequence the switching of RF amplifiers and pre-amplifiers so that the relays etc have enough time to switch RX to TX mode before RF power is applied. The Relay isolation that has been tested on the EME237-70CM Kit should easily allow up to 100Watts PEP( +50dBm ) of RF to be used.

2/ Transceivers including the ICOM IC-475, IC-1275, IC-820/821, IC-910, IC-9100, and IC-9700, have a pre amp switch with delay sequencing built in, so they are all able to directly power a pre-amplifier through the antennas coaxial cable connection so require no external bias tee.

3. For other Transceivers including the TS2000, TS2000X and IC706

series without inbuilt pre-amplifier switching and bias tee, the

pre-amplifier can be powered either by running a DC power cable

directly to the pre-amp board, or by feeding it up the coaxial

cable. For FM operation, the on-board RF sensing circuitry can be

simply used, but for SSB it is much better to use an external bias

tee to power through the coaxial cable. Many Transceivers have

access to a +12 volt TX connection on the accessories socket on the

rear. This can be used to control the bias tee switching the +12vdc

to the pre amp in RX mode, and disconnecting it in TX mode.

1/

2/ There have been reports of failure of the PGA-103 due to lightning damage. It is suggested that the pre-amplifier power is turned off when there are storms to prevent any damage. An option to fit a SMP-1330-005LF PIN Diode Limiter to D1 on the board could be tried, but this will increase the noise figure.

3/ Instability type noise that randomly lifts the S meter when in SSB mode was traced to a damaged PGA-103. It was suspected that it may have been damaged by excessive heat when soldering.

4/ Failure of the PSA-0012 amplifier IC2 has been traced to transmitting out of band RF into the pre-amplifier, ( namely 2M VHF ). The pre-amplifier has been designed for use in the 420-450MHz band only, and will not tolerate RF from a Transceiver including 144-148MHz being transmitted through it in TX bypass mode. The return loss and SWR is actually quite bad at VHF so any attempt to transmit though it will damage the pre-amplifier.

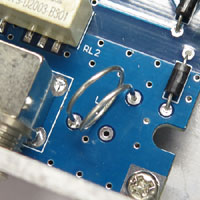

5/ The use of Axicom V23079G2003B301 Relays, and the Murata LQW2UASR33G00L Inductors ( L1/L6 ) are critical for the performance of the pre-amplifier. The inductors were chosen for the best relay isolation and transmit return loss. Replacing these with substitutes will probably damage the pre-amplifier due to RF power coupling through relays to the pre-amplifier.

6/ Low or intermittent gain has been traced to a faulty V23079G2003B301 Relay. Relays can be carefully removed by desoldering or cutting the relay leads, and then continuously wobbling the relay back and forth until the leads break on the side next to the TNC connector. Remove the left over leads with solder wick, and then clean the PCB before fitting a new relay. Some skill will be required to get a soldering iron in at an angle on the TNC side of the relay.