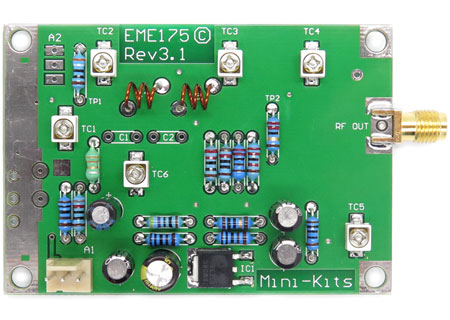

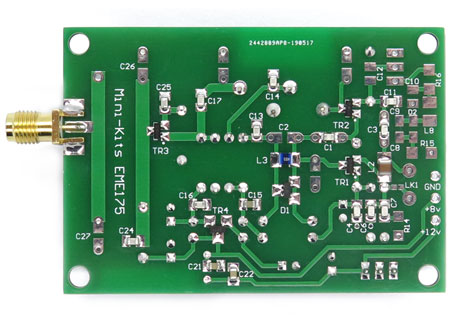

EME175-R3 Butler Oscillator Kit

The Mini-Kits The EME175-Rev3 Kit is an updated design that was released in June 2019 due to a number of leaded components that are no longer manufactured. The original EME65 circuit design that goes back to the 1990’s was updated in 2010 to the EME175-Rev2 with help from Kevin ZL1UJG and input from others, to evaluate the original Kit version to improve the performance. Improvements have been made to lower the power supply and oscillator phase noise, including the heat sinking and insulating requirement to use an optional temperature controlled heater. Depending on the Kit version and component options fitted, the oscillator will provide a frequency stable +7dBm output in the 400 to 640MHz range suitable for Transverters and RX Converters in the UHF to Microwave bands. With extensive changes to the tuned circuit components, the oscillator can be made to work down to 370MHz, and as high as 700MHz.

The Optional EME177 Oscillator Heater Kit has been designed to suit the EME175 Rev2 and 3 Kits, and ideal for use with high temperature cut crystals to obtain stability.

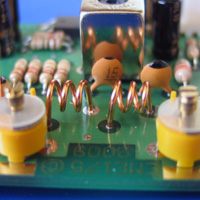

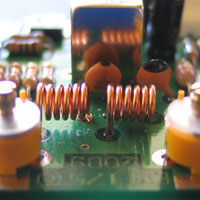

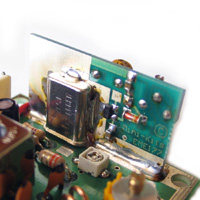

The images below show a Kit that was constructed for a 576MHz output. Take note how the coils are wound, as many tune up problems can be traced to the coils being incorrectly wound. This is a very difficult Kit to build and tune onto frequency, so it is only recommended for constructors that are very experienced in circuit design and have the required test equipment to tune it. The wound coils and trimmer capacitor positions are very critical, as the tuned circuits have to resonate at the correct harmonics of the crystals frequency. Using a low cost TinySA or other spectrum analyzer is very helpful to tune the trimmers to maximize output at the correct frequencies.

The main things to remember when mounting the oscillator into an enclosure is that it needs to have insulation to stop temperature changes from affecting the frequency. The easiest way it to use polystyrene foam inside the enclosure.

The recommended enclosure used below is a Hammond 1590S ( 110x82x40mm ), which allows enough room to line the enclosure in 10mm polystyrene insulation. The Pink foam shown below should not be used, as the density is too high so thermally it is not very good. I highly recommend that you use 10mm low density white polystyrene foam in the box, and if you fit it very tightly, then it is a very good insulator. The PC board is mounted to the bottom of the enclosure using 10mm metal spacers. The board is insulated from the spacers using plastic stepped transistor insulators to reduce heat transfer loss from the board to the enclosure. A piece of polystyrene could also be used across the middle of the enclosure to reduce the thermal gradient in the box. This may improve the temperature stability by not having as much air inside the box around the main oscillator section to keep at a constant temperature. The die cast enclosure can be obtained from RS Components part # 3642269. Expensive Feed through capacitors have been used for +12 volts and the Heater output temperature voltage, although you may want to use something more cost effective.

References:

These References are highly recommended for those that want to learn more about Crystals and Oscillator design.

1/ Crystal Quartz Resonators Ham Radio Magazine February 1986

2/ Crystals Made Clear Part 1 Electronics World September 1999

3/ Crystals Made Clear Part 2, Electronics World October 1999

4/ Solutions For Stable and Precise Microwave Frequency Generation, VHF Communications 2/2005

5/ Low Noise VHF Crystal Oscillators DK4XP, VHF Communications 4/2000

7/ www.vectron.com/products/ocxo/ocxos.htm

8/ https://wenzel.com/technical-resources/

The stability of the Oscillator can be calculated by testing the frequency drift in Hz. Then by entering the figures in to the calculator on SiTime the stability in PPM can be calculated.

1/ There are no current changes to this Kit.

2/ Oscillator starting issues are normally related to the resonant frequency of C2, L3, TC6 tuned circuit. The component values may need changing to resonate correctly for the crystals frequency for reliable starting. If the tuning is too far off then the oscillator will not start, so the circuit should be tuned to when the oscillator reliably starts when applying power. Placing a finger across the bottom of the PCB where the oscillator components are can initially help to start the oscillator for tuning TC6 and L3/C3 values.

3/ For 30pF load crystals it is recommended to use a 27 to 33pF capacitor ( excluding the 10pF trimmer TC1 ) for C3. The more capacitance used here will pull the crystals frequency lower at the expense of the TC1 trimmer capacitor only having a very small effect. In some cases C6 also had to be increased up to 47pF to reduce the frequency. These oscillators are very finniky and require some persistence to optimize. The adjustment of TC6 including the value of L3 will also cause pulling of the frequency.