EME65 Butler Oscillator Kit

- EME65/65B Kit Description:

Updated! June 2022 - Download the complete Kit Notes:

- EME65 Kit Construction Notes:

- Kit changes and Modifications:

- Buy a the replacement EME175 Oscillator Kit:

This Kit has been discontinued, so we do not recommend repairing this Kit due to the improvements that have been made with the replacement EME175-R3 Kit.

Presentation by Kevin ZL1UCG April 2009 Developing a 1296MHz Beacon. Includes references to the EME65B Kit. Download

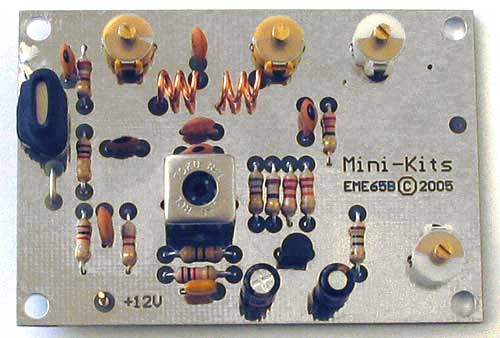

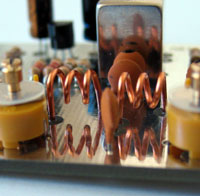

The images below show the different versions of the Kit. Take note how the coils are wound, as many tune up problems can be traced to the coils being incorrectly wound. The trimmer capacitor settings show the positions when using the crystal mentioned below. The Crystals case must be connected to the top of the board with a wire link for stability. An optional 50 degree C PTC Heater can be used with 50 degree cut crystals for temperature stability. The PTC is fitted up against the crystal, and a short length of heat shrink is used to hold it into place against the crystal.

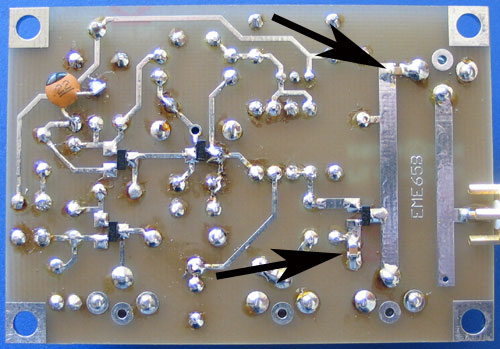

1/ New changes to Kits after September 17th 2009. These changes were to reduce spurious output by adding extra bypass capacitors and a schottky diode pack across the Toko coil. Solder a 1nF chip capacitor on the junction of the 560ohm resistor and L1 coil. The chip capacitor should be soldered between the 560ohm resistors lead and the ground plane on the top of the board. Solder a BAS70-04 schottky diode pack across the coil L1 on the bottom track side of the board. Solder a 22pF ceramic leaded capacitor from the 1kohm resistor that is connected to the emitter of the first BFR92A to ground. The capacitor is fitted on the bottom track side of the board and the leads are cut short. If you are still having trouble with spurious output when tuning then try changing the 78L08 to a 78L05 regulator that will reduce the gain of the oscillator stage with minimal affect on output power.

2/ There are a number of modifications below suggested by Kevin ZL1UCG that may improve the oscillators performance. You should only attempt these if you know what you are doing, and are only suggestions. A few changes can be made to the power supply to improve frequency stability and quality, ( reduce phase noise ), the 78L08 regulator was removed and replaced with a 15ohm resistor. A separate 7808T regulator is now used off the board to feed the complete oscillator. 10uF capacitors are fitted on each side of the regulator. Even better results can be obtained by using a very low noise regulator, as standard regulators are very noisy. Phase noise may also be reduced by fitting a 47uF capacitor from the base connection of the first BFR92A to ground, and replacing the 1kohm resistor between the bases of the two BFR92A transistors with a 1uH inductor. Also fitting a 1uH inductor in series with the 1kohm emitter resistor as shown may improve phase noise.

3/ The 27pF capacitor on the collector of the first BFR92A was replaced with a 10pF which significantly reduces the frequency change with power supply voltage. Applying notes 1 and 3 above significantly reduces the crystal dissipation. Excess crystal dissipation an affect drift aging and failure of the crystal.

4/ The 2nd multiplier also appears to be over dissipating and the 10ohm resistor can be replaced with a 100ohm and the interstage capacitor 15pF can be changed to 6.8pF. The output power is still around +10dbm output run off a 8 volt supply.

5/ A number of constructors have reported the 10ohm resistor burning up when tuning the 4th trimmer capacitor. The problem seems to be that some of the trimmers may be faulty and short out at some point where the trimmer is set. Check the trimmer with a multimeter if you have found this problem and replace if needed.

6/ If you have low output power and trimmer capacitor TC3 won't tune, then a common problem is one of the two chip capacitors that are soldered on the bottom of the board, many not be soldered on one end, or one is cracked.

7/ Many tune up problems can be traced to the two coils being wound incorrectly. Please refer to the pictures in the construction notes above on how they should look.

8/ The crystal frequency can be moved down approx 2kHz using a 100nH inductor in series with the crystal and around 15pF capacitance is seires is needed to move it up by the same amount. A small NPO trimmer capacitor can be tried in series with the crystal for fine tuning. Only use what is required to bring the crystal onto frequency. If the frequency of the crystal is way out, then the crystal should be replaced. The Toko coil should not be used to try and move the crystal frequency by more that a few hundred Hz else the oscillator becomes unstable.

9/ Tests by Kevin ZL1UCG on the Capacitor and Coil combination used in the Butler Oscillator eme65doc The chart has recommendations for the capacitor that should be used to resonate the tuned circuit correctly.